Fifty years doing anything is a mighty long time but to the incumbents of the Fesenmeier Brewing Co. of Huntington, the celebrating of their 50th anniversary of business this year will mark just another short milestone in an already gratifying career.

In fact, as Frank Fesenmeier, president of the company said during an interview this week, “this is only the beginning. The first 50 years were the hardest. Now we’re ready to begin.”

Quaffing a few ten-ounce glasses of lager in the Fesenmeier tap room, which is

an exquisite place with all the atmosphere of a genuine German beer garden,

Frank and his brother Gus, the present brewmaster; and tall, lean, affable

George J. Linsenmeyer, the sales and advertising manager for the firm –

discussed with the writer various possible ways of producing this story.

Mr. Linsenmeyer suggested a recapitulation of the brewery’s long and

respectable history here in Huntington. Frank and Gus nodded in assent.

However, newspapermen being hard-headed, this was rejected by the writer in

favor of another approach.

“LET’S GIVE them the story of the bottle or glass of beer” the writer

suggested. “Let’s give them the whole romance of producing your product.

People are afraid of history because there are too many dates.”

This idea was adopted unanimously.

So a few lagers later, in the company of George Linsenmeyer, this is the story

that unfolded before the eyes of a lay beer lover:

Beer is truly a beverage of moderation, manufactured with all the care,

integrity, and patience of great artists.

WITH COUNTLESS numbers of federal regulations to observe and with the ever

present shadow of a return to prohibition confronting them – the makers of

beer are truly people of stouthearted ken.

But they wouldn’t have it any other way.

“It makes us work harder and longer to present a temperate beverage that the

working man can consume in moments of relaxation, “George said. “It makes us

work harder to prove that we are in a respectable and fine business – free

from the stains of the many charges that are always being thrown at us.”

BUT GEORGE didn’t spend too much time philosophizing. Instead, in capsule

form, he completed a swift tour of his brewery explaining the story of a glass

or bottle of beer.

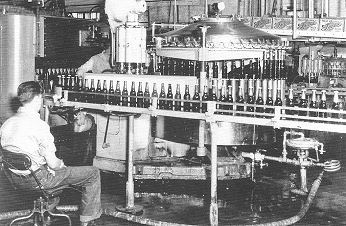

EVERY BOTTLE of beer that Fesenmeier's place on sale is

checked for purity and a lack of foreign substances. Shown here (left) is a

line of beer bottles which have just passed through the pasteurizer and have

been crowned with caps in the circular device seen in the center. They then

pass before the inspector, shown at the left, who with the aid of a powerful

light placed on the far side of the bottles, can detect any impurity that may

have crept into a bottle.

The first stop on this trip is the mash tub [tun] into which grain and water

are placed. The grains and water are agitated to get starch and sugar. In all,

this tub holds 300 barrels of water and 12,000 pounds of grain – which is in

the heavyweight class. Incidentally, the grains are malt and corn flakes.

When this step is completed, the grains are strained off from a liquid known

as wort, i.e., the name of the liquid when straining is completed. This takes

place is a lauter tank where the remaining grains are pushed into a hopper and

sold to farmers as cattle feed. During the process of straining in the lauter

tank, the grains gain 30 percent of proteins.

The wort is then drained off in tubs. The brewmaster, Gus Fesenmeier, checks

the liquid for clearness and if it isn’t clear, he pumps it back into the

lauter tank. If the liquid is found to be clear, he pumps it into a brew

kettle.

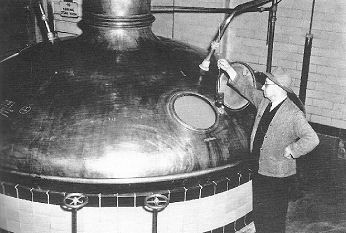

Made entirely of copper and resembling a giant tea kettle, the brew kettle is

one of the most picturesque pieces of equipment in the plant. In it, hops are

added to the wort or strained liquid. Eight u-shaped pipes fastened to its

sides force steam into the kettle in order to boil the wort.

This boiling is done to get the true essence of the hops into the liquid. In

the center of the kettle floor is a hop-strainer which handles the runoff from

the hops after the kettle’s chore has been finished.

AT THIS POINT the wort drops into the hot wort tank from the beer kettle. Any

sediment in the liquid will drop to the bottom of the tank while the wort

itself is pumped into a “cooler room.”

In the “cooler room,” which is its name and not a description of it, the beer

(we can call it that now) is pumped through to the top from which it trickles

down over copper and cast iron pipes. Ammonia is pumped through the copper

pipes and brine through the iron pipes, while the beer is trickling down. This

enables it to be cooled from 180 degrees to a chilly 40 degrees.

From the “cooler room” the beer is pumped into settling vats where yeast is

added. The beer remains here for a day which allows an activation of the

starch and sugar, causing fermentation. These vats, there are three of them,

are glass lined.

At this point, George pointed out that the brewing process of one batch of

beer would have reached 14 hours.

From the settling vats, the beer is pumped into the fermenting room where it

does just that (fermenting) for 10 days in order to attain the legal desired

alcohol content. While the fermenting is in progress, carbon dioxide is drawn

off and stored. It is later added to the beer for carbonation purposes.

All of the fermenting tanks are glass lined and after they are emptied, they

are subjected to a thorough scrubbing and an inspection for chipping.

Next the batch of beer is pumped into a stock room or

cellar where a temperature of 34 degrees is maintained. Here the beer is

pumped into more glass lined tanks for an aging period which varies between 50

and 60 days. It has a capacity of 15,000 barrels which, by the way is

4,950,000 bottles of beer. (A lot, huh?)

FROM THE STOCK room the beer is sent to one of two places. If it is to be used

in draught taps it is pumped into a racking room or if it is to be bottled it

goes to a bottling house at one end of the brewery’s grounds.

Just outside the stock room is a government meter which keeps check on every

drop of beer that goes into the racking or bottling rooms.

In the racking room the beer is filtered and then pumped into a racking

machine, where through tubes, it enters a keg, while air is drawn off from the

keg at the same time.

There is a special keg washing room where all kegs are washed in an alkaline

solution before going into the racking room to take on a load of beer.

EACH WASHED keg is lined with pitch, also.

In the bottling room, returned bottles are fed into a bottle washer where they

pass through five solutions of alkali and are brushed inside and out four

times. To top this off, each bottle is rinsed four times inside and out.

“And, everything we use to clean the bottles with,” George said, “is

thoroughly scrubbed and cleansed too.”

“Just like the Army,” was the writer’s comment, with tongue in cheek.

After being washed and scrubbed and rinsed, the bottles are fed into a filler

and from the filler to a crowning machine.

After passing the crowning machine the bottles go through a pasteurizer and

then are labeled, with each label dated in code. From the labeler the bottles

are fed into cases – and from the cases they go onto the trucks – from the

trucks to the stores – from the stores to your kitchen ice box.

That’s the story of beer. Anyone who thinks creating a batch of grog is

amateur stuff had better re-read the process. For, in all of these stages

there are trained men working under Gus Fesenmeier – men who know how to ply

their trade.

Fesenmeier’s brewery is one of 400 left in this country – where formerly there

were 2,000, with the 1,600 delinquent breweries becoming so because of the

expansion of the larger ones.

It is the only brewery in West Virginia.

It has a reputation in the art of brewing as one of the best in the country –

ranking high in the first third.

It produces between 80,000 and 90,000 barrels of beer a year or between

29,700,000 to 30,000,000 bottles a year.

FRANK FESENMEIER added a final, natural touch to the story when he said,

“People are constantly calling us up and demanding that we go out and clean up

the beer gardens. We’d like nothing better – but we don’t have the power to do

so."